Understanding our shock dyno

Posted by Dežru Performance Suspension on Aug 28th 2025

Dežru Shock Valving Explained

Why These Dampers Are Tuned for the Spring — Not a Wide Adjustment Gimmick

When people see a shock dyno for the first time, one of the most common questions is:

“Why isn’t there a huge gap between soft and hard on rebound?”

The answer is simple — because the damper is already tuned correctly for the spring and the car.

The shock is engineered so the usable adjustment range sits where the car actually performs best, not spread across extremes that make the soft side underdamped or the hard side overdamped.

The Philosophy: Tune the Damper to the Spring

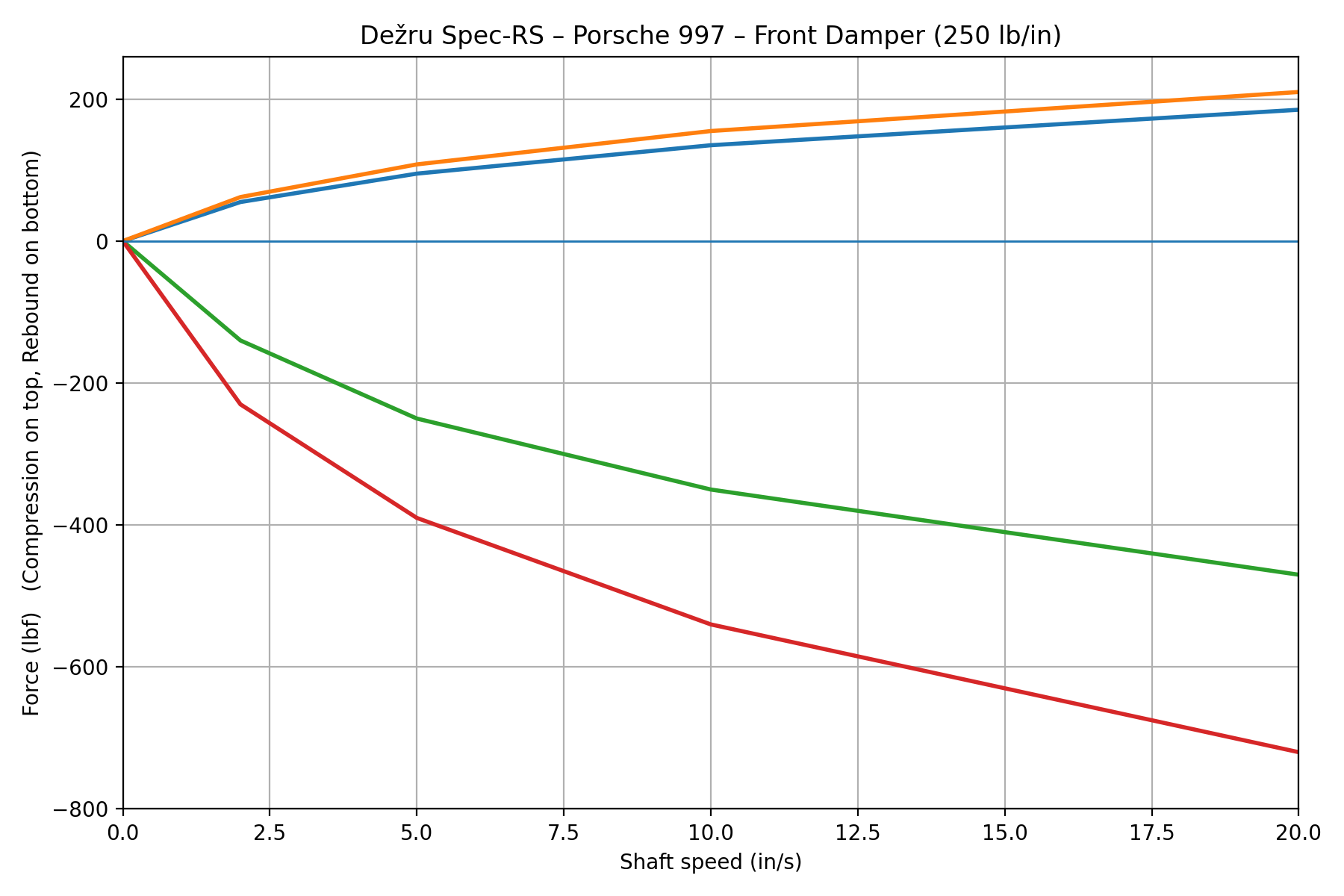

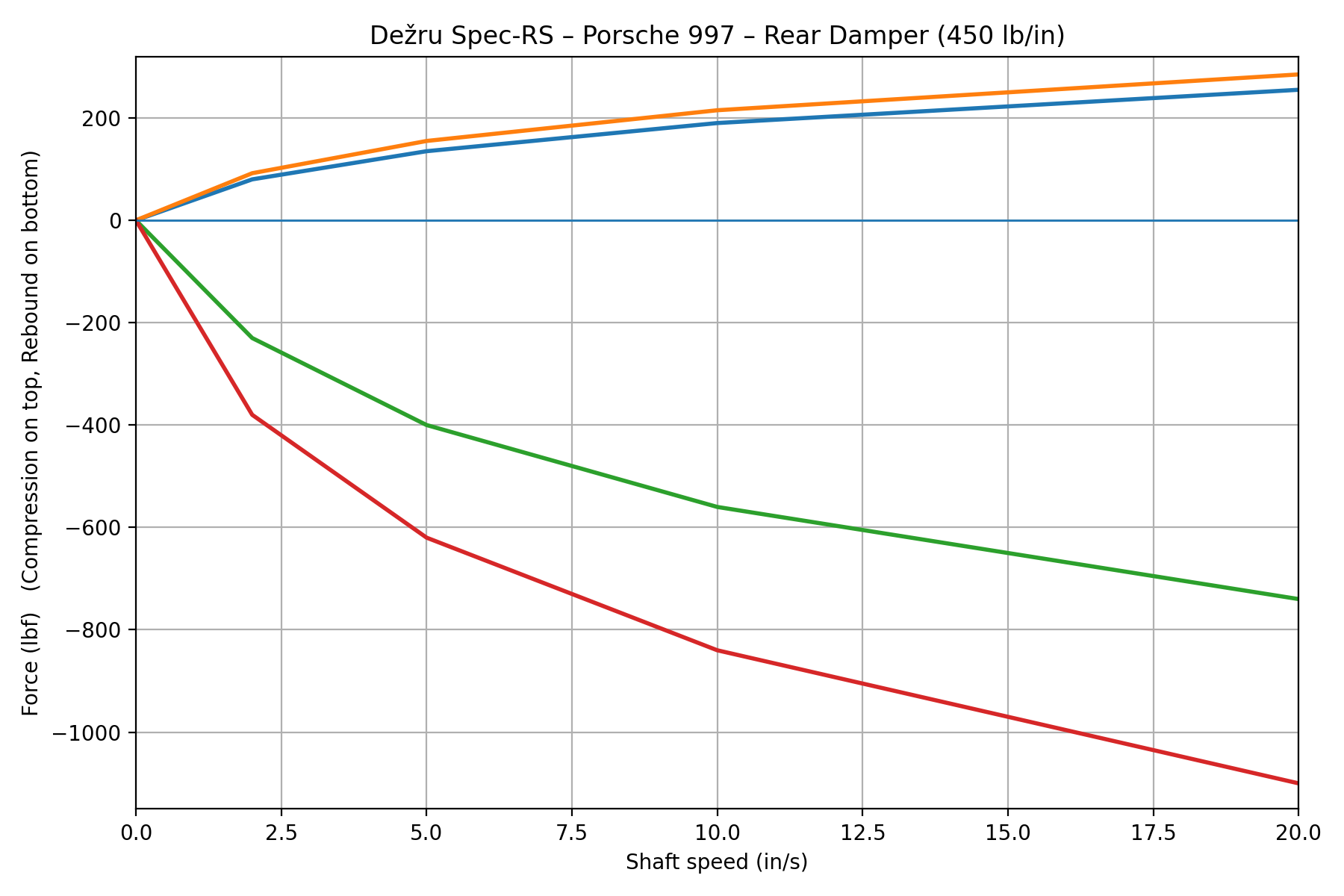

Every Dežru suspension kit is built around a defined spring rate and vehicle platform, for example:

- Porsche 997 front: 250 lb/in

- Porsche 997 rear: 450 lb/in

Those rates are chosen based on vehicle weight, motion ratios, balance targets, and intended use. Once the spring is selected, the damper is valved to control that specific spring.

A damper’s job is not to make a car stiff. Its job is to control spring energy.

Too little rebound feels floaty and unstable. Too much rebound reduces compliance and grip.

The shock baseline places the middle of the adjustment range right in the optimal control window for the spring it is paired with.

Why the Rebound Range Is Focused

Looking at the dyno curves, you’ll notice:

- Digressive rebound profiles

- Clear but controlled adjustment changes

- No exaggerated separation between soft and hard

That is intentional.

A huge rebound range often means only a small portion is truly usable. The rest becomes either underdamped or overdamped.

Dežru concentrates the range where it matters:

- Slightly softer for rough roads or low-grip surfaces

- Slightly firmer for smooth pavement or track use

Every click produces a meaningful change without letting the setup drift into poor tuning.

Digressive Rebound: Control Without Harshness

The dyno plots show a digressive rebound profile.

This provides:

- Strong low-speed body control

- Flattening force at higher shaft speeds

- Compliance over bumps

- Consistent tire contact

The result is a car that feels planted but not punishing.

1-Way Adjustment and Minimal Cross-Talk

The shock is a true 1-way adjustable damper.

The adjuster primarily affects rebound while compression is fixed and pre-engineered.

A properly designed 1-way damper has little to no cross-talk between rebound and compression.

So when you adjust rebound:

- You are not drastically altering compression

- You are not destabilizing the platform

- You are fine-tuning behavior, not re-engineering the shock

This keeps the setup predictable and repeatable.

What This Means on the Road and Track

Drivers typically notice:

- Stable corner entry

- Controlled weight transfer

- Compliance on imperfect pavement

- Predictable behavior at the limit

Most drivers find a sweet spot quickly and leave it there — a sign the base valving is doing its job.

The Takeaway

If you expect soft to feel like a marshmallow and hard to feel like a brick, this is not that.

Our suspension is engineered so:

- The damper matches the spring

- The adjustment range is fully usable

- The car remains composed across conditions

- Adjustments are fine-tuning, not band-aids

This is engineering-first tuning, not marketing-first tuning.

And that is exactly why the dyno looks the way it does: